|

|

|

|

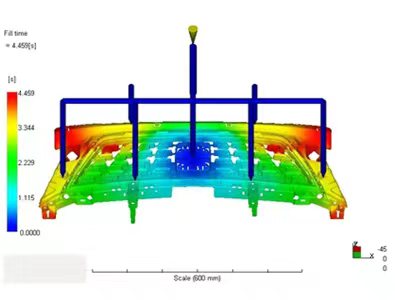

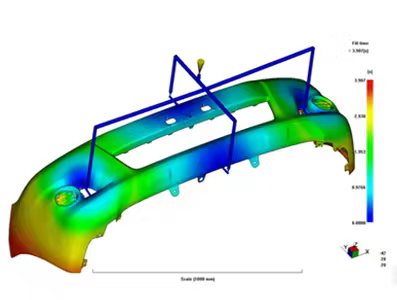

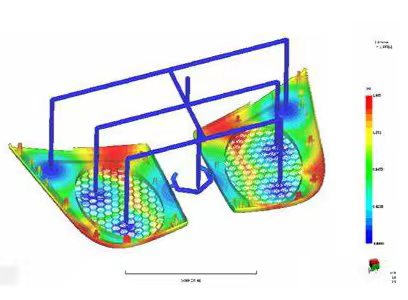

Before tooling production begins, Maiya uses Moldflow software to analyze the proposed mold design to ensure that the mold will be capable of producing the strongest, most uniform parts from each cavity.

Using customer-supplied part design, a computer model of the mold is constructed. The Moldflow software then uses this model and the processing characteristics of the specified resin to predict how the resin will flow through the mold and into the cavities. This allows various key molding attributes, such as melt temperature, pressure profile or time-to-fill, to be studied and optimized virtually before the mold is built. Moldflow points out potential tooling-related molding problems and allows them to be corrected prior to cutting steel. In this way, costly and time-consuming tooling rework is avoided.

|

||

|

Moldflow Filling Analysis Optimize gating Optimize runner system Predict fill pattern Predict injection pressure Determine clamp tonnage Predict temperatures Visualize shear rate Visualize shear stress Determine fiber orientation Predict volumetric shrinkage Predict sink Determine venting Avoid air traps Locate weld (knit) lines Develop optimum ram-speed profile |

Moldflow Cooling Analysis Find hot spots Calculate time to freeze Visualize uneven cooling across core and cavity Determine uneven cooling between core and cavity Define required coolant flow rates Measure pressure drop in cooling system Determine (and reduce) cycle time Optimize the cooling layout

Moldflow Packing Analysis Calculate proper packing pressure Define optimum packing profile |

Moldflow Warpage Analysis Predict warpage Find cause of warpage Determine warpage due to orientation Predict warpage due to differential cooling Understand warpage due to differential shrinkage

Moldflow Gas-Assist Analysis Determine optimized gas channel layout Predict gas penetration See gas permeation Predict skin/core ratio Establish required gas pressure Define optimized gas pressure profile Refine spillover design |